Experience in all types of metal processing and mass production.

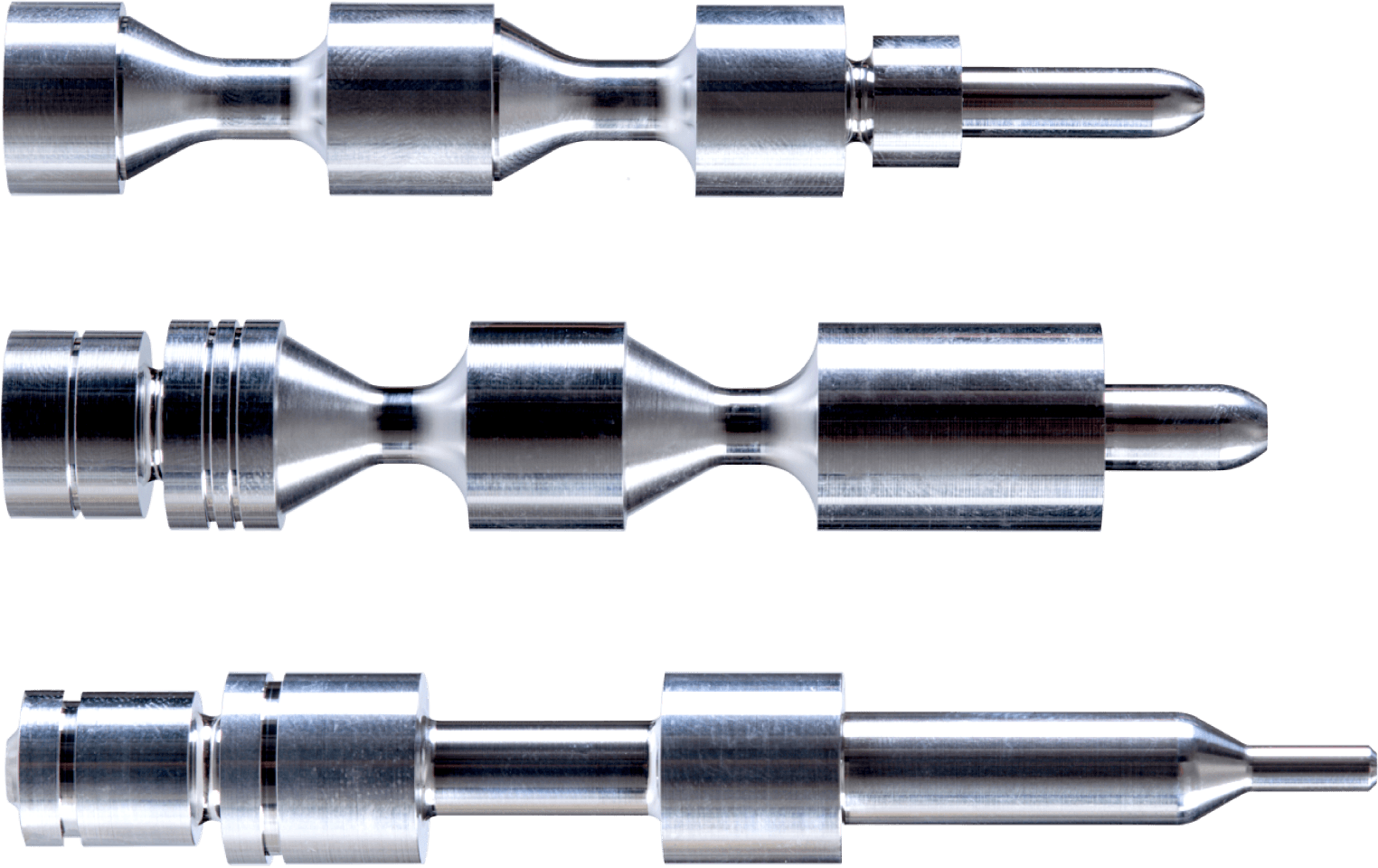

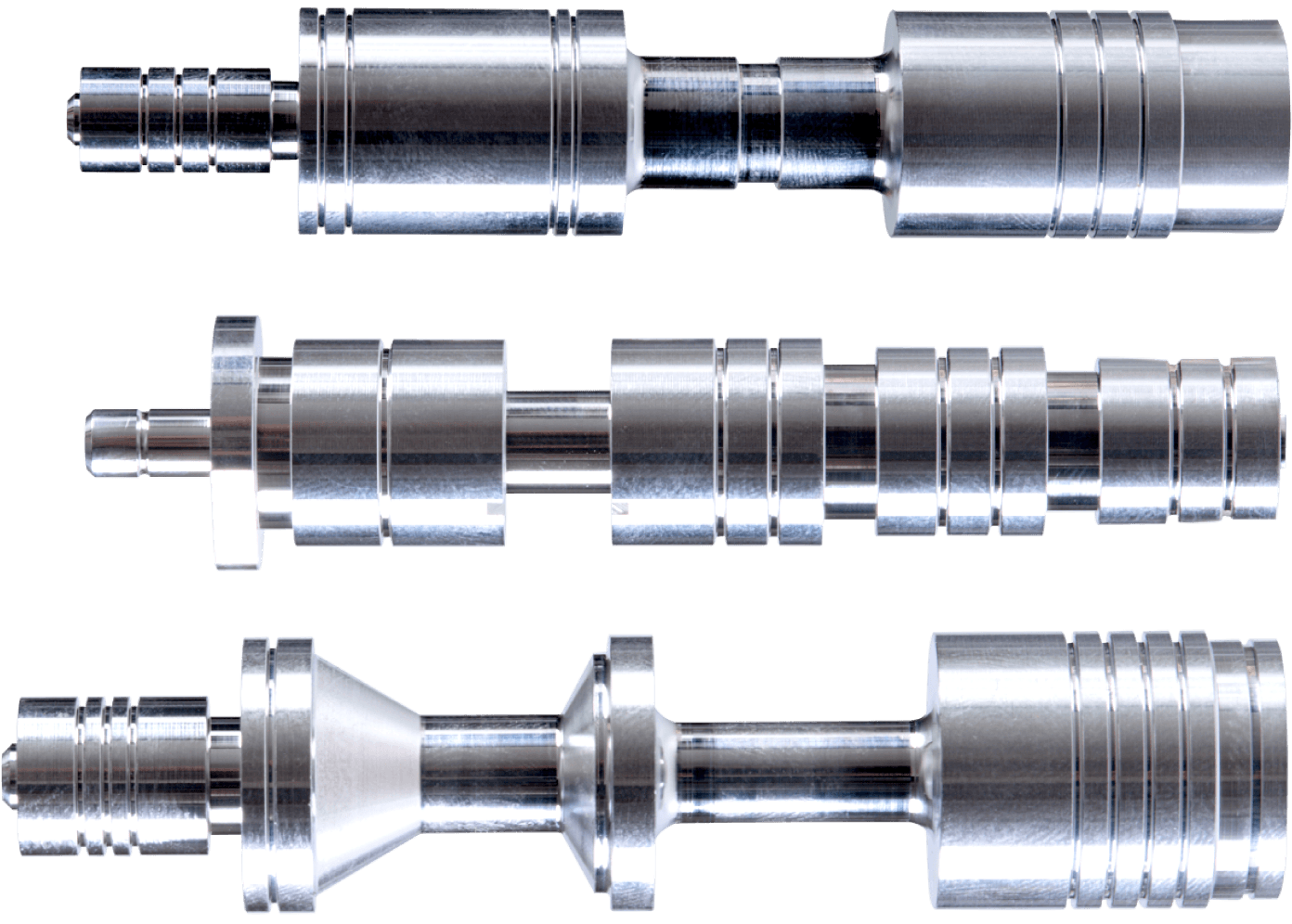

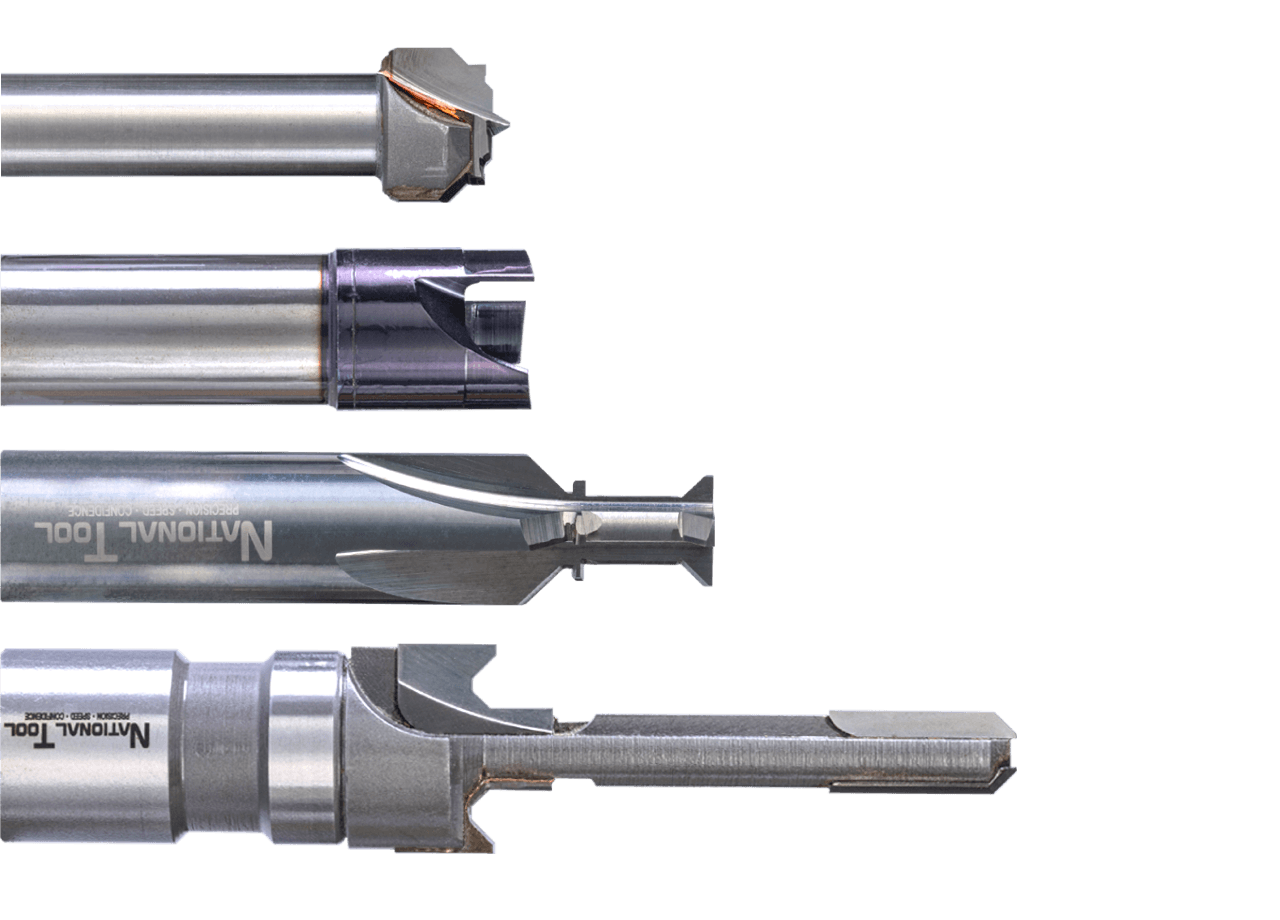

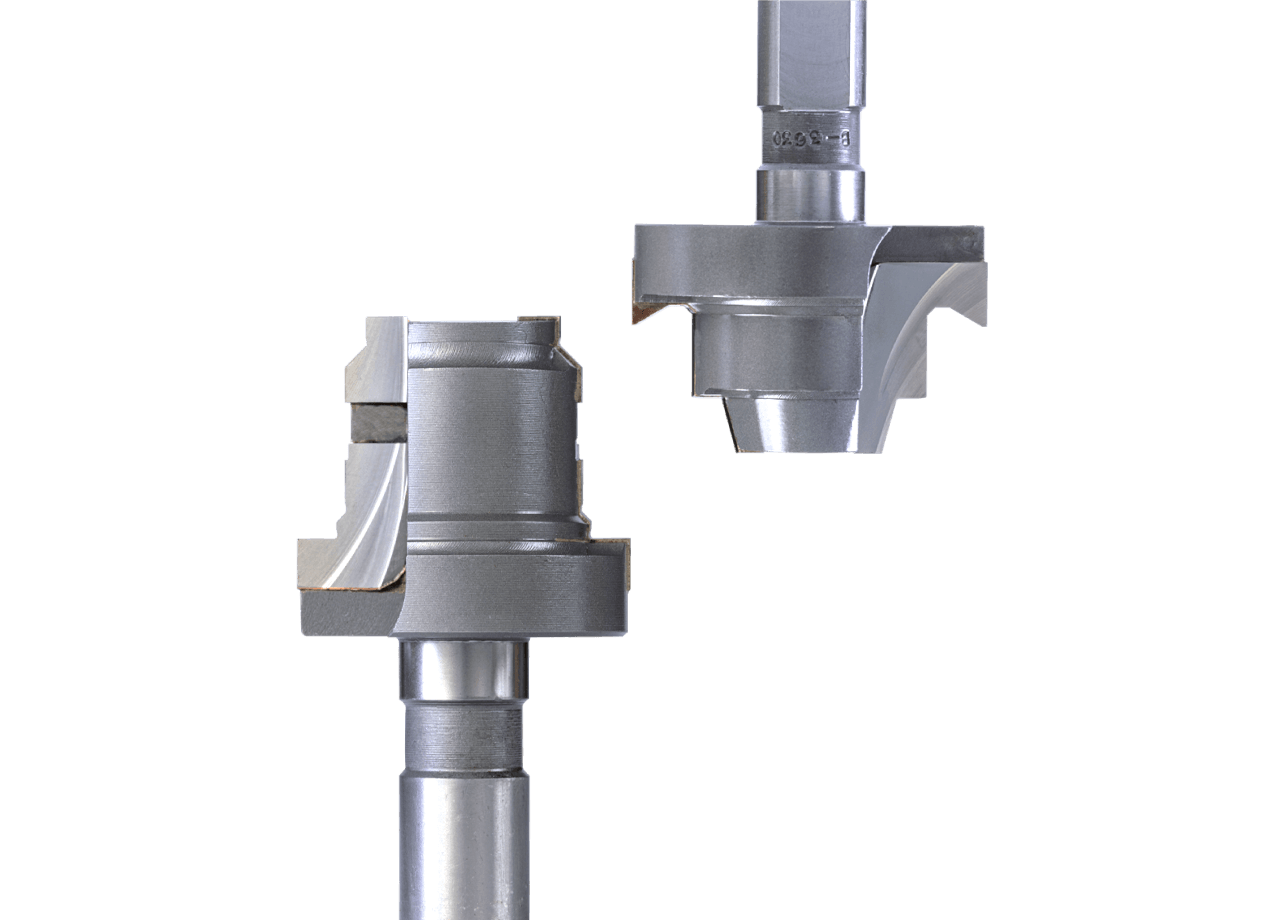

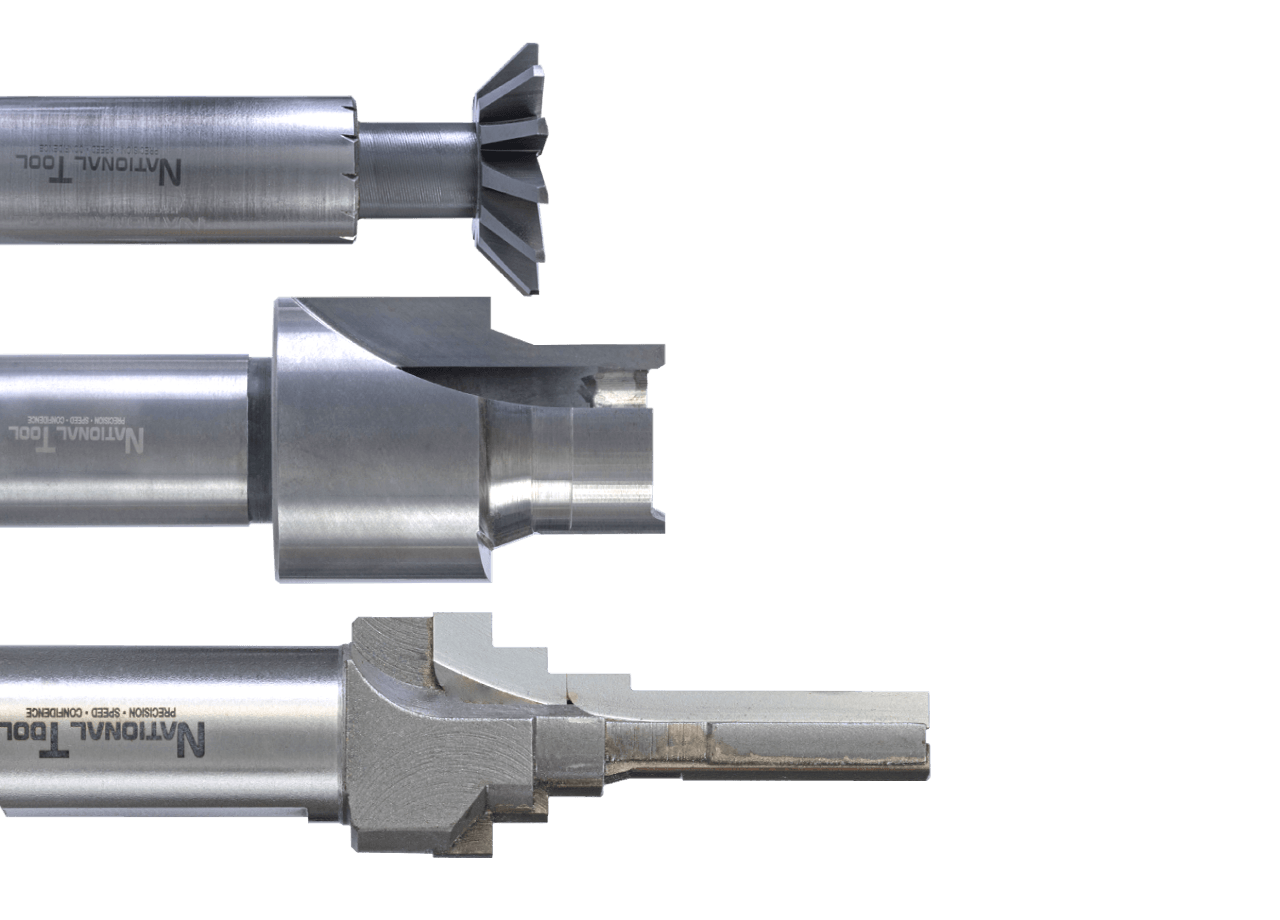

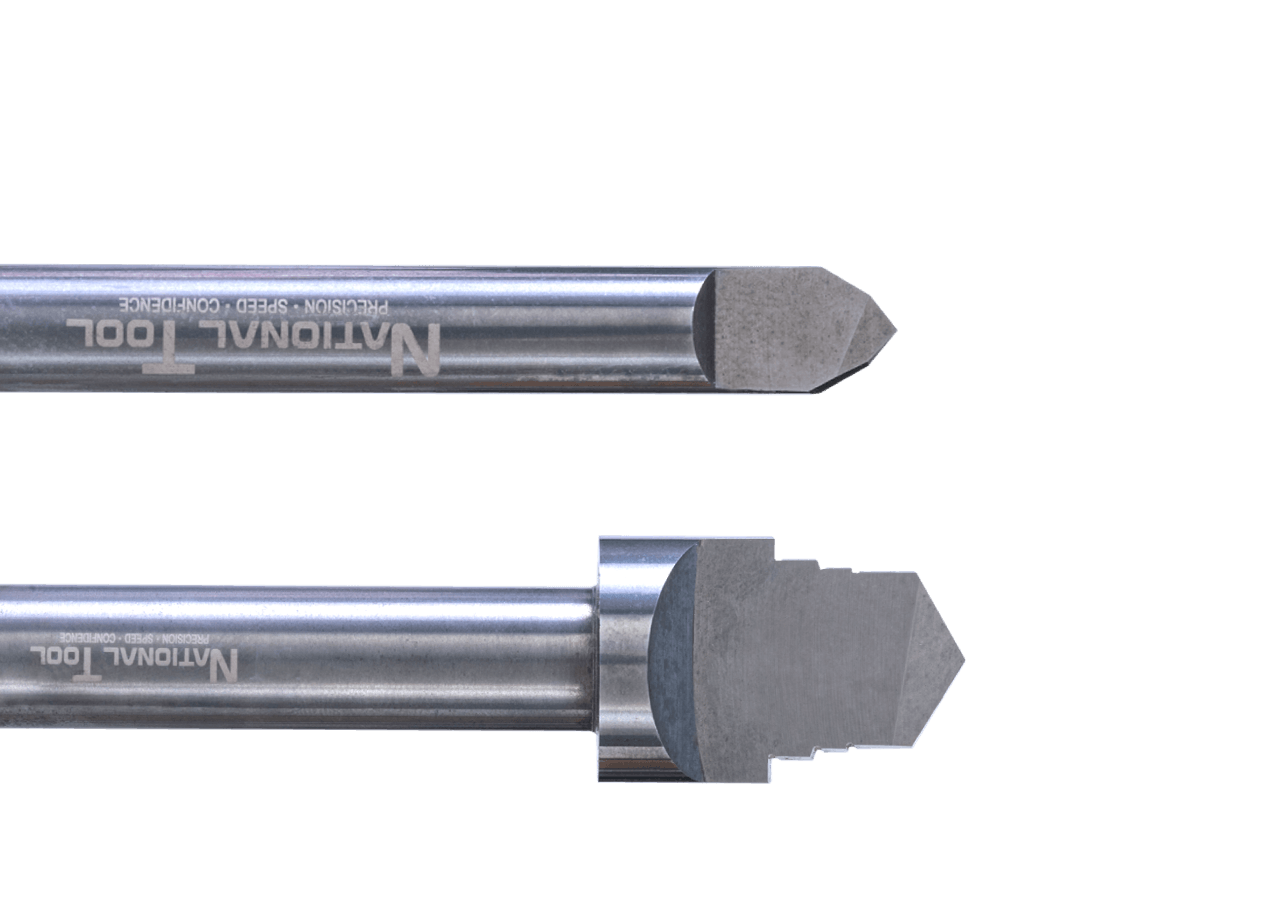

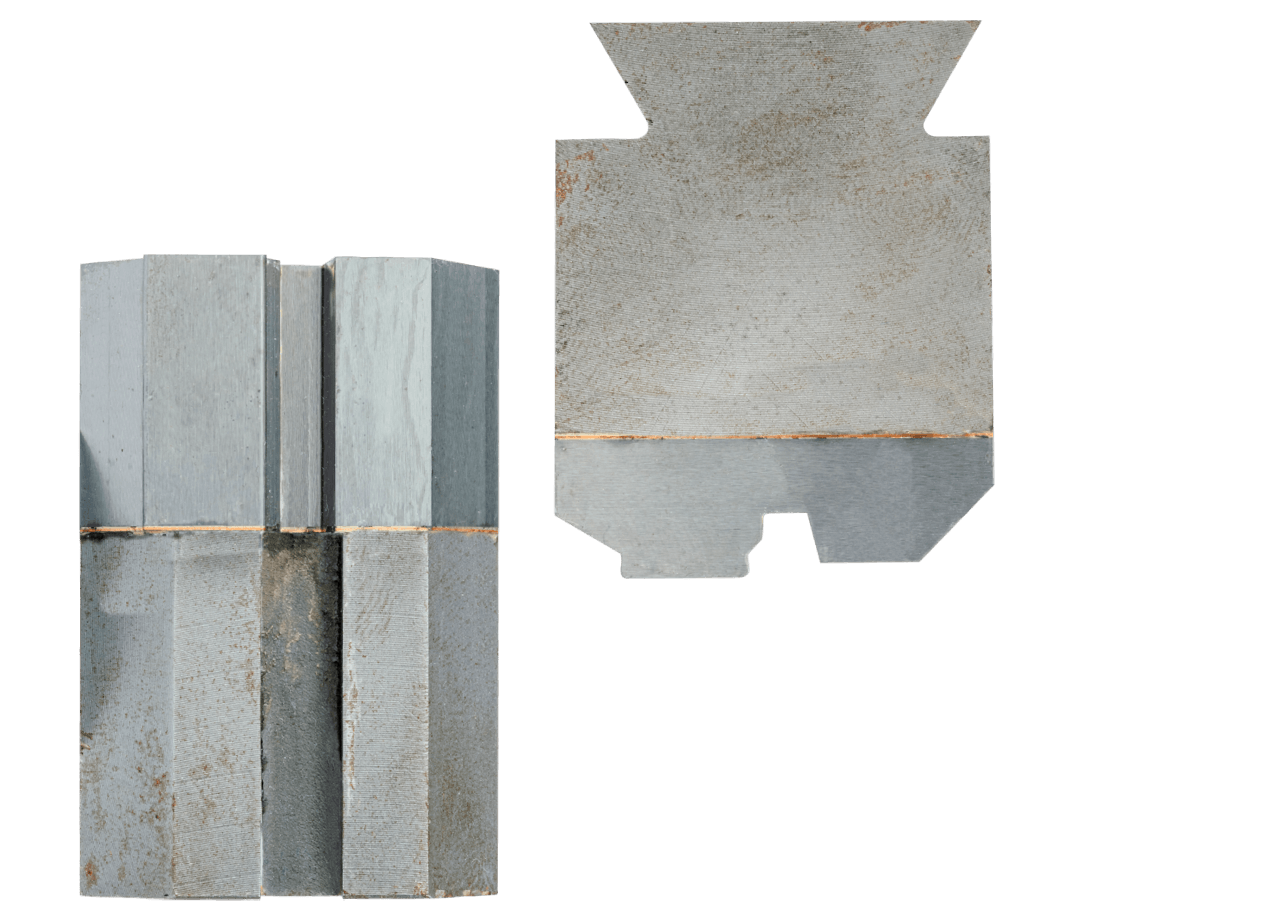

Utilizing our in-house tool design and manufacturing know-how, we overcame the unique stickiness and softness of aluminum processing, which was a key issue in reducing the weight of AT components in automobile parts, and achieved 24-hour production.

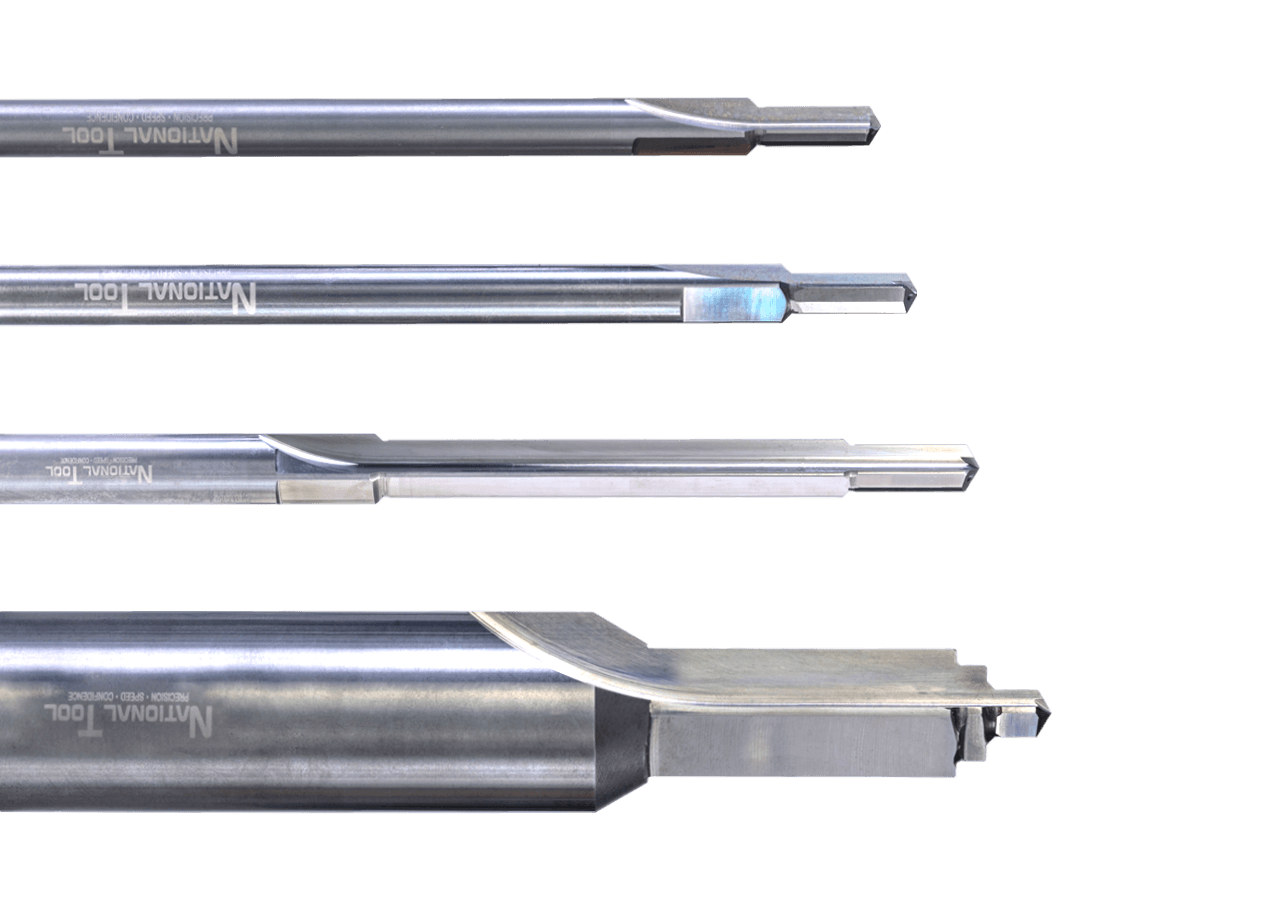

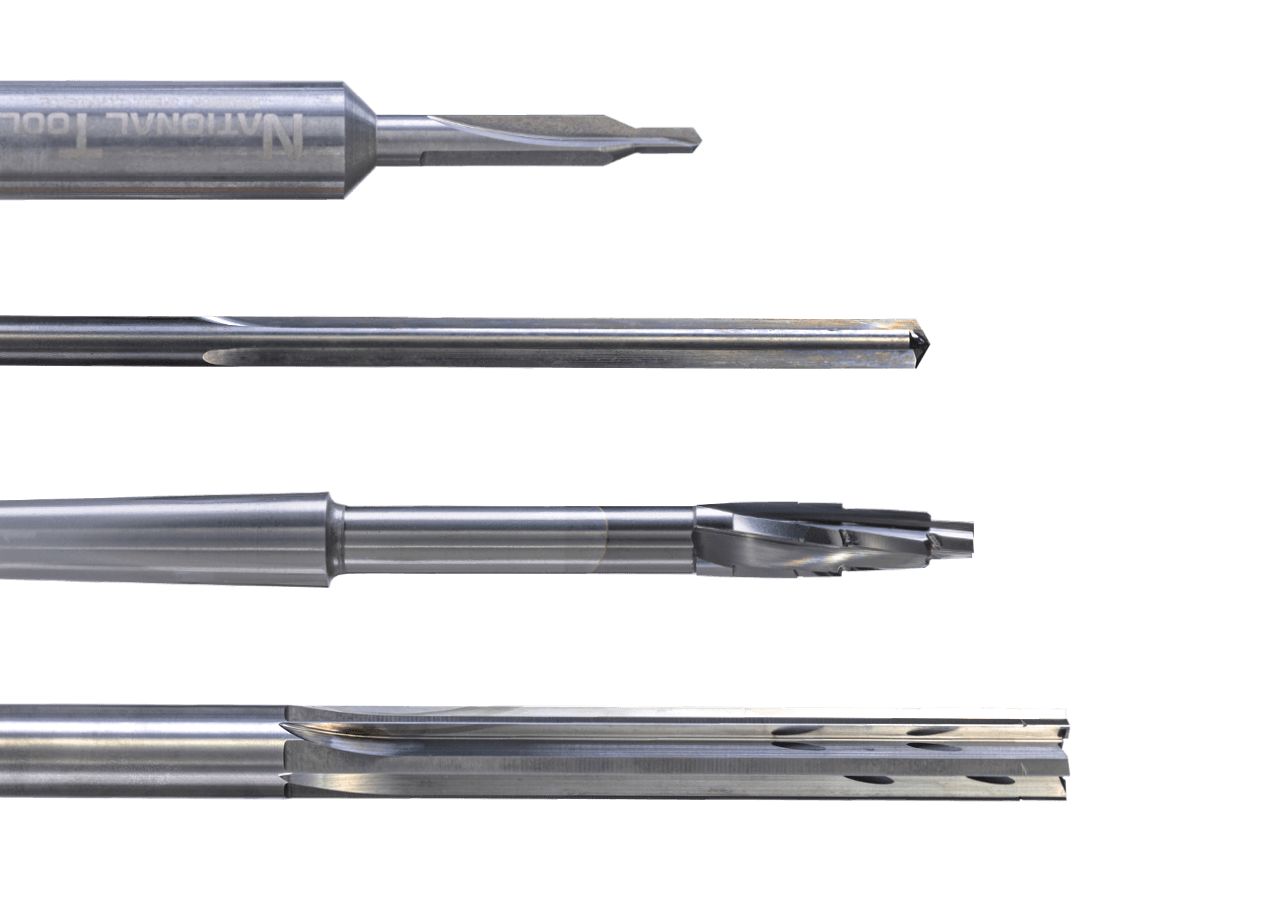

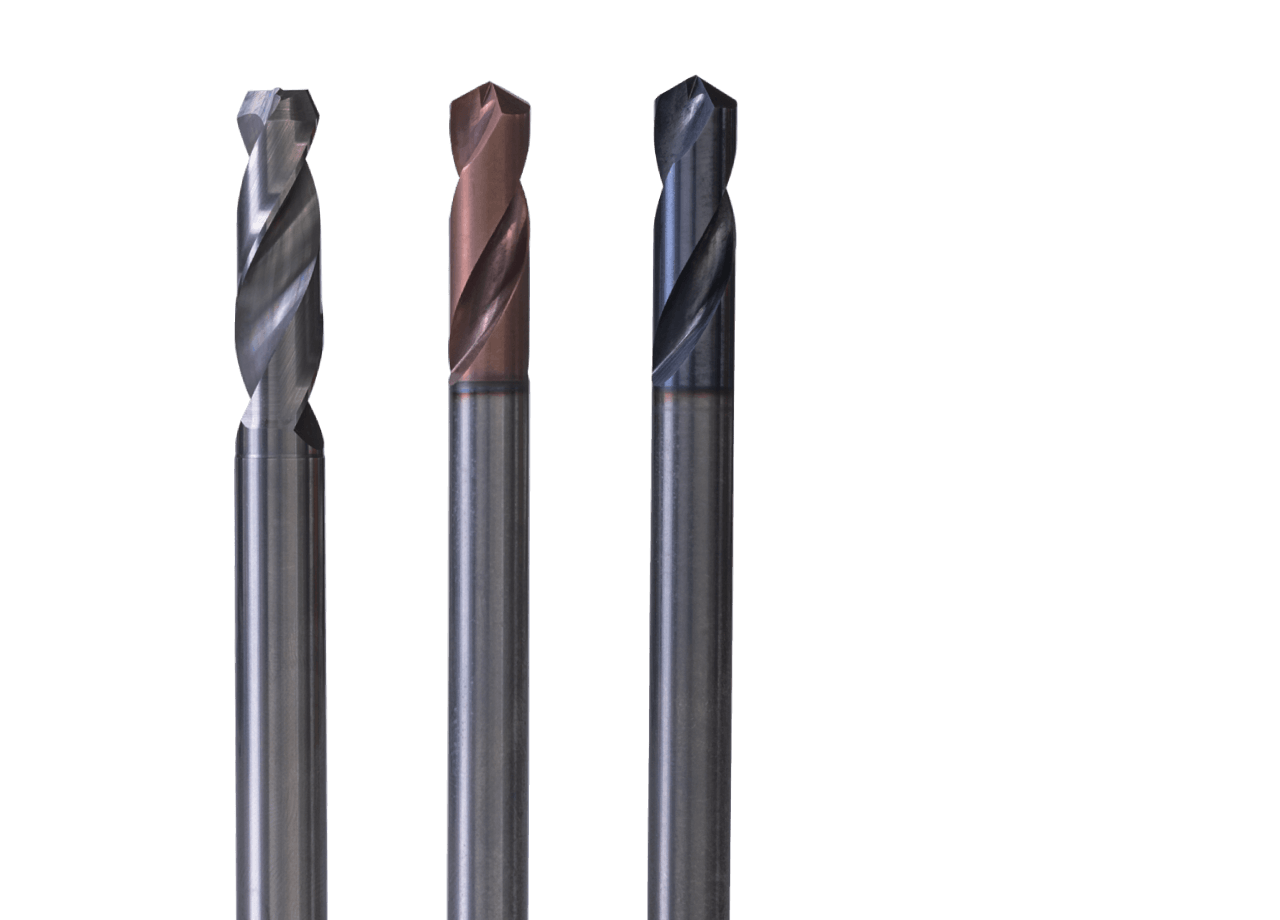

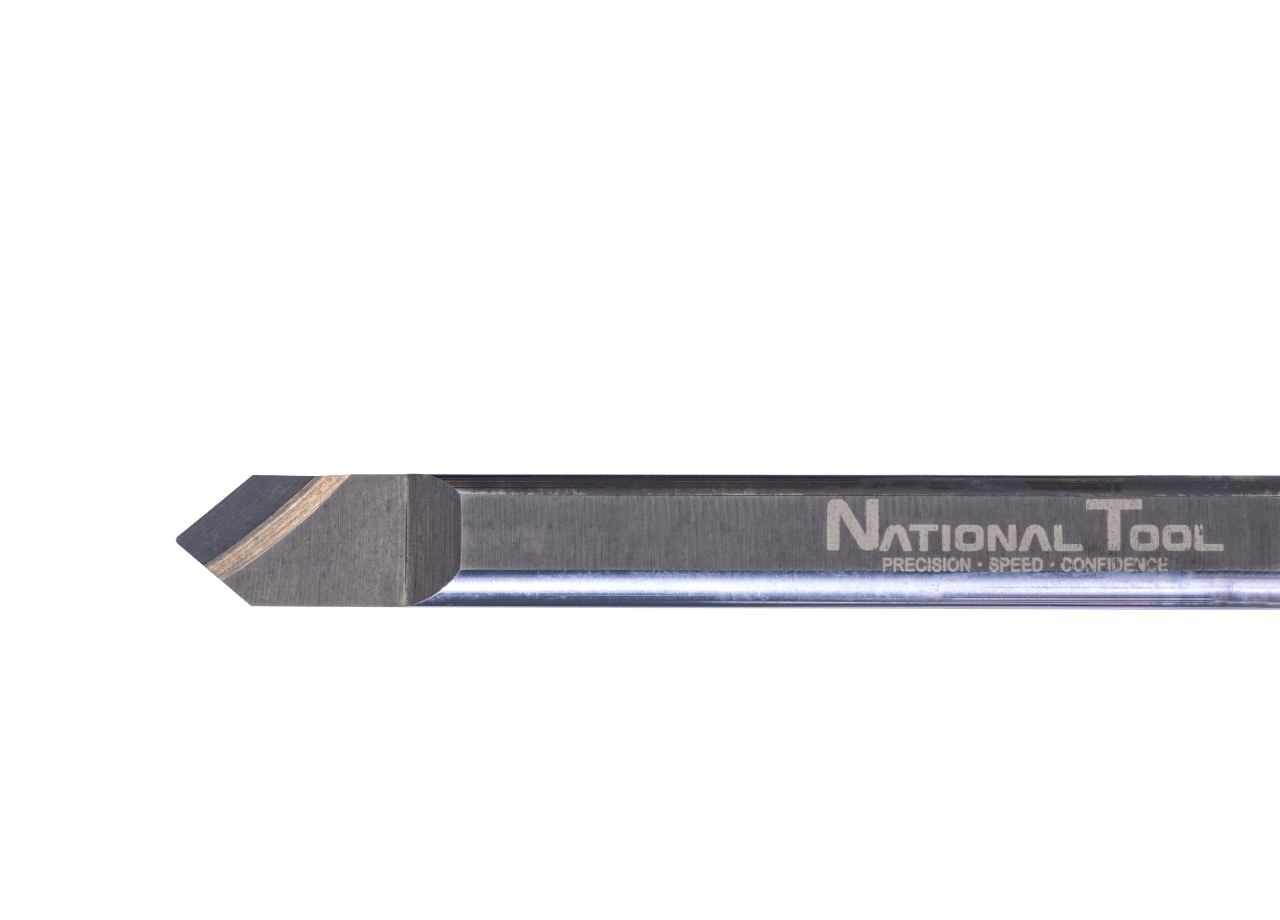

By using in-house designed and manufactured tools for difficult-to-cut materials, we differentiate ourselves from other companies through our own unique tool layout.